We aim to build long-term, mutually beneficial relationships with our business partners. We believe that better sustainability performance can enhance the overall resilience of our value chain, while helping supply chain partners mitigate ESG-related risks, operate at greater resource efficiency, enhance their reputation, and capture new business opportunities.

We wish to empower our suppliers to understand, track and improve their sustainability performance and, more importantly, to identify new collaboration opportunities with our partners to innovate sustainability practices.

1. New Supplier Selection

Our e-Contractor List Management System is integrated with our vendor requisition process in Hong Kong and the Chinese Mainland. This automated platform facilitates supplier selection, management and performance analysis and allows for timely updates of supplier information. For new suppliers to be included on the list of approved contractors, they must first complete self-assessment questionnaires to confirm they have appropriate policies and systems in place to comply with our SCoC.

2. Existing Supplier Monitoring

We monitor the compliance status of suppliers on our approved contractors list on an ongoing basis. In addition to requesting regular self-assessments, we may also undertake supplier site visits, request that our suppliers obtain independent certification in accordance with internationally recognised standards, and submit environmental and health and safety management plans for our internal review. We may also arrange regular performance review meetings with selected significant suppliers to communicate emerging ESG issues and any follow-up actions required for continuous improvement.

We continuously refine the performance management system for our technical services providers. Any act of non-compliance or malpractice in the areas of health and safety, environment, procurement, quality and site management is recorded, and the technical provider will be subject to disciplinary action. In 2023, there were no incidents of human rights violations identified across our operations.

3. Understanding and Managing the ESG Risks of our Significant Suppliers

To effectively implement our SCoC and improve the data transparency, accuracy and reliability of our Scope 3 emissions generated from our supply chain, we introduced our Business Partner Sustainability Programme as a key initiative this year.

NaN / 3

3a. Supplier Screening

Supplier screening is conducted annually to identify the top 300 Tier-1 suppliers by considering the significance of their potential exposure to ESG impacts (related to country, industry sector and the impact of the commodity), and the significance of their business relevance (including suppliers’ criticality, volume, spending, and substitutability).

3b. Supply Chain ESG Assessments

This year, we partnered with EcoVadis to become the first real estate company in Hong Kong and the Chinese Mainland to launch a supply chain sustainability engagement programme through the EcoVadis’ proprietary ESG assessment platform. EcoVadis provides a robust, comprehensive and internationally aligned methodology to assessing our supplier’s ESG performance. Furthermore, EcoVadis’ evidence-based approach enhances the credibility and reputability of its third-party verification. The programme will be rolled out to our significant suppliers identified in the supplier screening phase based on a three-year assessment cycle, and will follow the process outlined below:

- Supplier onboarding webinar – Conduct webinars to introduce our pilot suppliers to the programme, sharing our company's ambition and providing details about the assessment process. The webinar provides suppliers with an overview of the assessment process and highlights the importance of supply chain sustainability and ESG risk management in their operations.

- Customised questionnaire – Suppliers receive a customised questionnaire tailored to their industry, country of operation and company size. The questionnaire is designed to capture information on the company’s management practices on 21 sustainability criteria encompassing environmental considerations, labour and human rights, ethics and sustainable procurement. It is structured in alignment with our SCoC and with reference to international sustainability standards such as the Ten Principles of the UN Global Compact, the International Labour Organization Conventions, the Global Reporting Initiative (“GRI”) standards, the ISO 26000 standard, the CERES Roadmap, and the UN Guiding Principles on Business and Human Rights.

- Carbon disclosure – Suppliers are invited to provide relevant information including their carbon management systems, strategy and performance.

- News watch – The ESG assessment platform utilises a comprehensive news monitoring system that scans over 100,000 data sources, including NGOs, press outlets and trade unions. This process combines AI and human analysis to identify relevant sustainability practices of the company over the past five years, both positive and negative. It also incorporates data from the Global Regulatory Information Database.

The supplier’s responses and findings will then be distilled, analysed and summarised into a scorecard. Suppliers will receive detailed insights into their strengths and suggested improvement areas, and will be able to benchmark and compare their ESG performance against participating peers.

Swire Properties will regularise the assessment of supplier performance based on their risk exposure, allowing us to report and track progress over time, efficiently monitor suppliers’ corrective actions, provide technical support for implementation, and continuously improve the accuracy, reliability and transparency of information.

3c. Continuous Supplier Development – Benchmarking and Capacity Building

Following the assessments, participating suppliers are provided information on the best ESG practices in their industry and given a priority list of improvement areas. These can help the suppliers implement corrective actions and make improvement plans. Suppliers are also given access to the EcoVadis’ online e-learning platform, that contains courses on sustainability and ESG management practices. The course material covers policies, actions and reporting across a variety of sustainability themes as well as broader topics such as training, certification and risk management. This platform is a valuable resource, giving the suppliers knowledge and skills that will contribute to their overall sustainability performance and enhance their ability to meet the evolving expectations of stakeholders.

The supply chain ESG assessment was piloted with our top 60 significant suppliers in 2023. The pilot programme has received a positive response from suppliers with a participation rate of over 70%. These suppliers are based in Hong Kong, the Chinese Mainland and the U.S.A.

According to our findings, none of these suppliers were considered “high risk” under our Enterprise Risk Management System or have substantial negative impacts to our business operations.

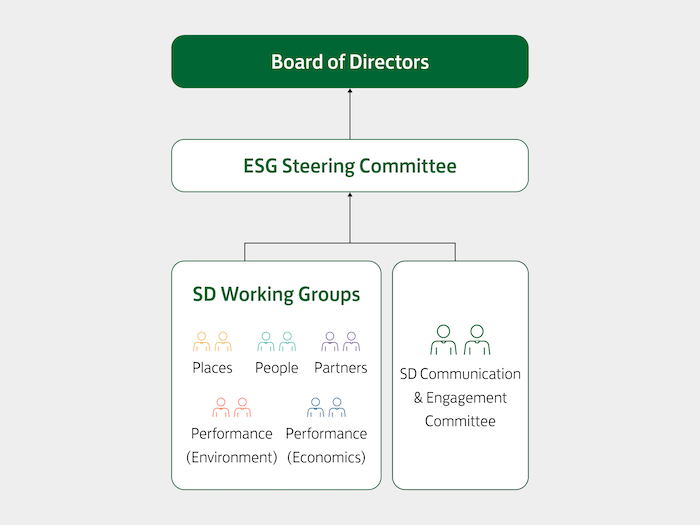

We provide regular training for the Company’s buyers and relevant internal stakeholders on their roles in the programme. The programme is regularly reviewed by the Partners Working Group and the progress is reported to and monitored by the ESG Steering Committee.

See More In

NaN / 3