Swire Properties’ Zero Harm Commitment includes working towards fostering a culture of health and safety best practice with all our partners. Beyond our day-to-day operations and the management of existing properties, this culture also applies to projects under development and all related construction sites.

In 2023, we continued our enhanced collection and public reporting of health and safety-related metrics and incident reports from contractors that was introduced in 2021. This approach allows us to track performance and work with our partners to develop strategies that improve on-site health and safety performance, ensuring that all our construction sites are safe places to work. Our ambitious internal construction accident rate target is used to guide our efforts in this area.

We also continued our use of various safety-oriented smart technologies at several construction sites in Hong Kong and the Chinese Mainland. These ranged from using robots to conduct more dangerous tasks to issuing workers with smart devices that keep them safe on sites, along with several others.

In 2023 we also continued to partner with our contractors to adopt innovative technologies to improve site safety during the construction stage of our new projects. Initiatives included a semi-autonomous ceiling drilling robot trialled on the Six Pacific Place project, and smart cloud-based construction monitoring platforms adopted for the Chai Wan residential development project in Hong Kong, as well as the Taikoo Li Xi’an and Sanya projects development in the Chinese Mainland. We also launched our health and safety roadmap which included Design for Safety initiatives to involve our design consultants and contractors in proactively identifying and addressing potential safety hazards and risks early in the project lifecycle.

Number of Fatalities of Contractor Workers

0

A contractor fatality is defined as a loss of life of a contractor or subcontractor employee as the result of an incident occurring when those contractor or subcontractor employees are conducting work for our Company.

Lost Time Injury Rate of Contractor Workers at Hong Kong Development Projects

0.24

The Lost Time Injury Rate (“LTIR”) represents the number of injuries per 100 contractor workers per year. It is calculated as “total number of injuries multiplied by 200,000 and then divided by total hours worked”. The factor of 200,000 is the annual hours worked by 100 contractor workers, based on 40 hours per week for 50 weeks a year.

Accident Rate of Contractor Workers at Hong Kong Development Projects

3.46

The accident rate represents the number of reportable accidents per 1,000 contractor workers. It is calculated as “total number of reportable accidents multiplied by 1,000 and then divided by average daily number of contractor workers on site”.

Smart Construction Technology in Hong Kong

Supporting the Smart Site Safety System Initiative

This year, Swire Properties supported the Hong Kong Development Bureau’s Smart Site Safety System (“SSSS”) initiative, using various technologies and systems to enhance the management of safety at our construction sites. These included:

- Smart safety insights. Gained through smart platforms with AI video analytic cameras, IoT sensors and smart wearables to monitor site safety. We used our award-winning CONDUCTOR platform at Six Pacific Place9 and the C-Smart platform at our Chai Wan residential development.

- Smart construction techniques. These included a water leakage test pilot project at Two Taikoo Place which was then extended to Six Pacific Place; and a robot used for lift installation and overhead drilling to increase safety and efficiency at Six Pacific Place. Another robotic system was used to test the water permeability of the project’s curtain wall, reducing the risk of working at height.

- Smart training. We used VR training at all our active development sites and adopted virtual rehearsals for high-risk tasks before performing the actual work at Six Pacific Place and the Queensway Bridge project.

Supporting the Smart Site Safety System Initiative

NaN / 3

9 | CONDUCTOR is a dedicated tool that allows users to monitor multiple construction data streams and multiple construction sites at once, greatly enhancing efficiency, task management and safety. |

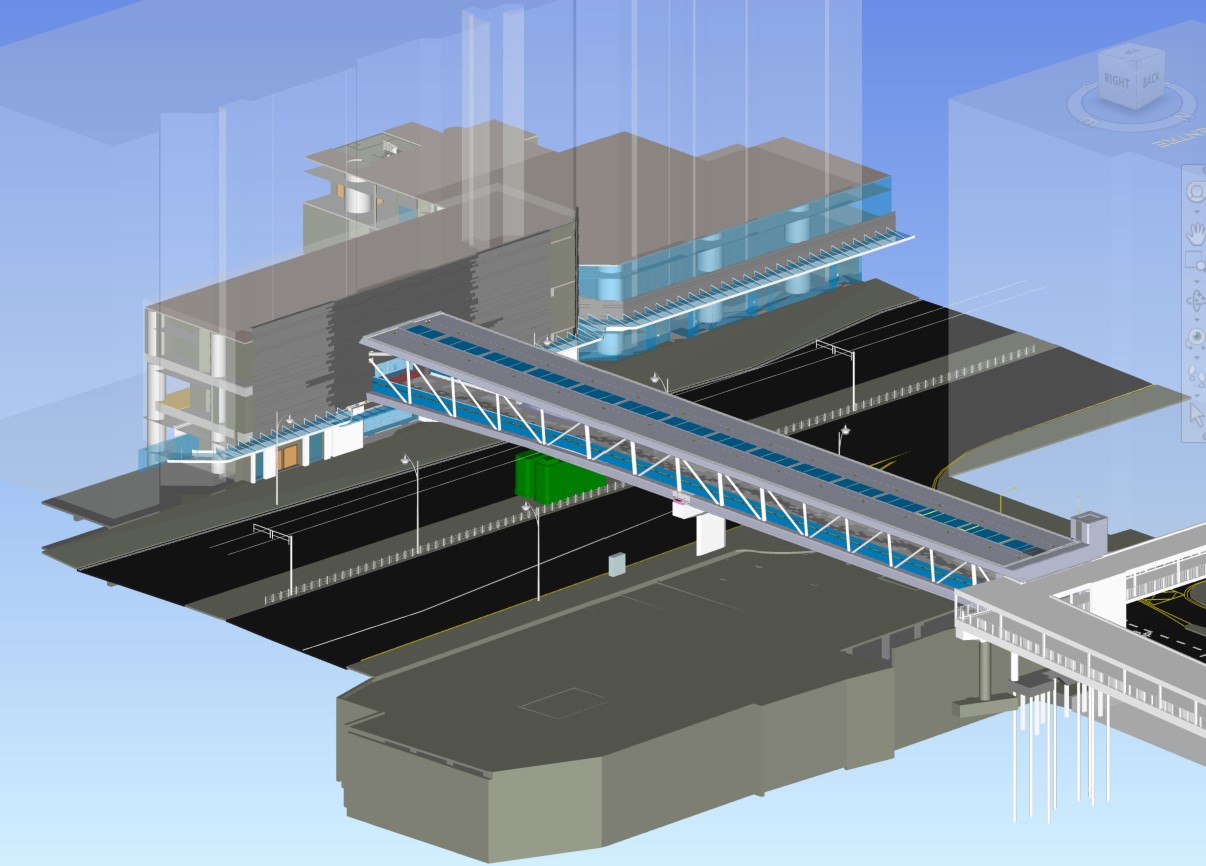

Design for Manufacture and Assembly at the Queensway Footbridge Two

The Design for Manufacture and Assembly (“DfMA”) construction approach involves manufacturing large building components at an off-site location and then assembling them on site. DfMA is being used for the steel structures for the Queensway Footbridge Two project, simplifying the fabrication, delivery and erection of the steel modules for the approximately 350 tonnes of steelwork for the footbridge. The footbridge is divided into nine main segments, with each segment divided further into six major components with a maximum weight of 12 tonnes each. These segments are being fabricated in the Chinese Mainland and will be delivered by trailers to the Admiralty site in Hong Kong, allowing the bridge to be assembled safely and efficiently and with minimal public disturbance. Construction is expected to be completed by the end of 2025.

By using DfMA, the total embodied carbon is being reduced from approximately 900 tonnes of CO2e to 870 tonnes of CO2e, as compared to the conventional fabrication, delivery and installation method, due to the materials savings that have been achieved.

Design for Manufacture and Assembly at the Queensway Footbridge Two

NaN / 3

Safety Management and Smart Technology in the Chinese Mainland

Smart Safety Monitoring Systems

We continued to use smart safety monitoring systems at all our Chinese Mainland project sites throughout the year. By monitoring various construction site parameters using advanced sensors, data-collection devices and real-time monitoring, the systems improve safety, prevent accidents and ensure compliance with safety regulations.

Intelligent Safety Inspection Systems

Safety inspections of equipment and facilities have become digitalised and intelligent due to the rapid evolution of smart technology. Each of our management offices in the Chinese Mainland now conducts daily safety inspections of equipment and facilities and integrates this into their data centre inspection systems. This has reduced staff workload, mitigated safety risks and created closed-loop management systems that use big data, data analysis and early warnings that create timely alarms in case of anomalies. In Taikoo Hui Guangzhou, a robotic inspection and monitoring system was installed to monitor and report on plant-room conditions.

Intelligent Safety Inspection Systems

NaN / 2

Swire Properties Recognised with Multiple H&S Awards

Throughout 2023, we engaged our contractors in health and safety measures at all our development projects. Their efforts towards continuously improving their health and safety performance were recognised by the industry multiple times this year through awards in open competitions organised by the Hong Kong government and the Construction Industry Council.

Six Pacific Place

- Gold Award in the 29th Considerate Contractor Site Award

- Gold Award in the Innovation Award for Safety & Environmental Excellence

- Gold Award in the Developer (Private Sector) category in the CIC Sustainable Construction Award 2023

- Silver Award in the Outstanding Environmental Management Performance Awards

- Bronze Award in the Best Management Group category at the 15th Hong Kong Outstanding OSH Employee Award

Dorset House & PCCW Retail Conversion Works and Taikoo Place Internal Street Works

- Merit Award in the Considerate Contractor Site Award

Queensway Footbridge

- Merit Award in Life First 2023 – Walk the Talk Award

- Outstanding Award at the Joyful@Health Workplace Best Practices Awards (Enterprise/Organisation Category) in the 18th Occupational Health Award 2022-23

Chai Wan Residential Development

- Excellent Award in Life First 2023 – Walk the Talk Award

Swire Properties Recognised with Multiple H&S Awards

See More In

NaN / 3